The application of 3D printing in the field of intelligent textiles

3D printing has greatly promoted the development of smart textiles. Smart textiles made by 3D printing have the advantages of significantly reducing manufacturing costs, effectively simplifying the manufacturing process, combining multiple materials, enhancing the performance and quality of fabrics, and achieving sustainable manufacturing.

Forming method

There are four forming methods for 3D printing technology: bonding forming, photosensitive forming, fusion forming and selective laser sintering forming. Each method is applicable to different materials.

The diversification of forming methods is a testament to the current mature development of 3D printing technology in the textile industry. Bonding forming technology is a manifestation of the mature development of coloring processes in textile product design. Specifically, it involves combining colorants with bonding materials to form a thin layer and apply coloring. Photosensitive technology is a manufacturing process that uses photosensitive materials (UV resin) to form and stack under the effect of light. Melt forming is a process where thermoplastic materials are melted in a high-temperature cavity to form a liquid, which is then evenly sprayed out by a nozzle and superimposed to form the shape. It can be seen from this that the application of these technologies has changed the manufacturing methods of textile products and even influenced the production mode of the clothing industry. Therefore, 3D printing technology has a profound impact on textile products.

Smart textiles can incorporate optical fibers, phase change materials, chemicals or other electronic components, adding new functions to ordinary textiles. More and more textile materials are attempting to directly manufacture smart textiles with complex functions using 3D printing technology. Current research mainly focuses on areas such as conductivity, shape memory, temperature regulation, and flexible electronic components.

Intelligent conductive textiles

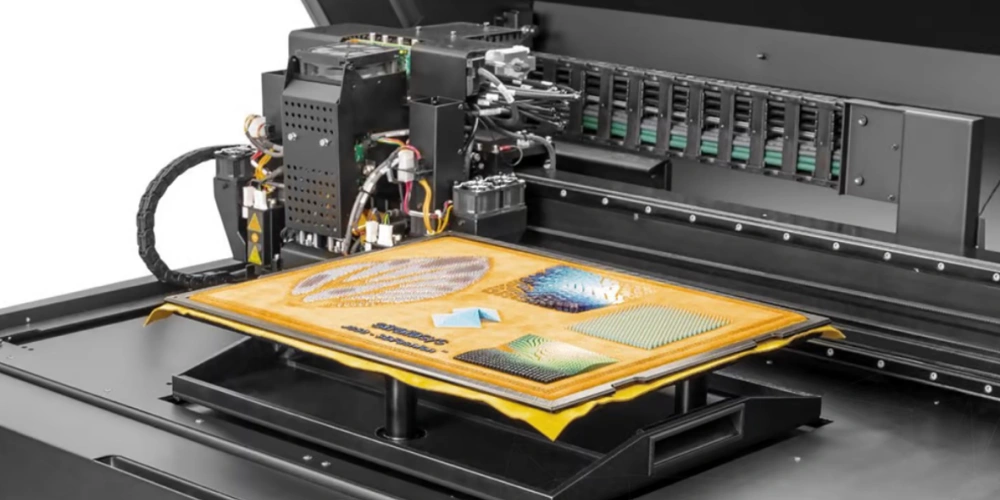

The most common method for developing conductive textiles is to attach conductive materials to the fabric surface. The implementation methods include lamination, coating, printing, spraying, ion plating, chemical plating, vacuum metallization, cathodic sputtering and chemical vapor deposition, etc. 3D printers can accurately print out the defined shapes. In this way, conductive yarns or coatings can be connected, especially to leadless SMD(Surface Mount Device) components. Meanwhile, 3D printing can adjust the structure of electronic components to achieve the most suitable structural state for the fabric. Grimmelsmanna and others from the University of Applied Sciences Bielefeld in Germany used 3D printing technology to directly print on fabrics containing circuit paths woven with conductive Shieldex yarns, enabling the 3D-printed objects to serve as conductive wires and connect with small electronic components, thereby making the textiles glow, as shown in the following figure.

As the textile base material, a single-sided hook-stitch knitted fabric with a textured effect and a relatively compact and uniform surface was selected, enabling the 3D printing material to bond better with the fabric. The developer designed an SMD-LED electronic component, which was manufactured on the surface of a textile substrate using FDM technology. SMD.LED is composed of three parts: black conductive material, non-conductive white PLA material and LED. The black conductive part mainly serves the function of electrical connection. The material used is Proto-Pasta conductive PLA filament. The extruder temperature is 207 ℃, the print bed temperature is 60 ℃, the layer height is 0.2mm, and the structure is filled. The white part is made of ordinary PLA filament, which serves to fix and connect. Black filaments with conductive properties are connected to Shieldex yarns to light up the leds on the textiles. The 3D printed component serves as a series resistor to protect the LED from being overexposed to high application voltages that could affect its normal operation. When the internal anode is low, the brightness of the LED is also low. This is because the LED and the 3D printed component are connected in series with a anode to work as a divider. The higher the anode, the higher the voltage rise.

Intelligent temperature-controlled textiles

There are various types of smart textiles with temperature regulation capabilities. For instance, the most common temperature and humidity regulating textiles on the current market lower human body temperature by removing excess moisture. However, such textiles can only be triggered when the air between the body and the fabric is at a high humidity level, which limits their application when the humidity level is low. In addition, there are other temperature control technologies, including cold bag textiles with phase change materials, air-cooled textiles and liquid-cooled textiles, etc., but they all have their limitations. To solve such problems, researchers have done a great deal of work in developing heat-regulating textiles. The University of Maryland has used a composite material with boron nitride nanosheets (BNNSs) embedded in a polyvinyl alcohol (PVA) polymer matrix for 3D printing to create smart temperature-controlled textiles that can rapidly lower human body temperature.

BNNSs has a two-dimensional structure and an in-plane thermal conductivity as high as 2,000 W/(m·K). To take advantage of the in-plane thermal performance of BNNSs, the sheet must have a good arrangement direction and uniform dispersion. Due to the fact that BNNSS can promote structural stability through the absorption of polymers during ultrasonic treatment in PVA solution, uniform dispersion can be achieved. Meanwhile, during the fiber printing and further thermal drawing process, the nanocomposite fibers are introduced through uniaxial extension flow, in which BNNSs forms a good alignment direction. Thus, an energy path for phonon heat conduction is formed. Highly oriented and interconnected, it can provide more heat conduction pathways, thereby effectively enhancing the thermal performance of a-BN/PVA composite fibers. a-BN/PVA textiles can release the additional heat generated by the human body along the fibers. Textiles release the extra heat generated by the human body along the fibers into the surrounding environment, thereby providing a thermally comfortable microclimate for the human body to achieve the purpose of cooling.

Shape memory textiles

Shape memory polymer is a kind of polymer that can remember its original shape. Under certain conditions, its shape can be changed, and it can be restored to its original shape by applying stimuli such as heat, electricity and magnetic fields. Polylactic acid (PLA), the most commonly used shape memory polymer, is also a frequently employed material in 3D printing. Therefore, shape memory polymers can be fabricated through 3D printing technology. At present, the research on printing shape memory polymers using 3D printing technology mainly involves two aspects of materials. One is to use 100% pure polylactic acid as the shape memory polymer. However, since the polylactic acid material can extend by up to 10% at most, the structure needs to be designed before printing to overcome such limitations. Langford et al. used a herringbone origami structure to solve this problem, as shown in the figure. It is a 3D printed object with a herringbone origami structure.

When folded, the volume of an object decreases. When unfolded, the volume of the object increases, but a few fine cracks appear on it.

The constant recovery rate of PLA filament is usually about 61%, while the recovery rate of the herringbone origami structure increases to approximately 96%. Another type is 3D printing using polylactic acid composite materials. Guido Ehrmann and Andrea Ehrmann used an FDM 3D printer to mix 80% PLA with 20% Fe04 to form a solid mixture, which was then crushed and extruded in a twin-screw extruder to print a porous trabecular bone structure, as shown in the figure. By applying an alternating magnetic field of 30 KHz, over 95% of the shape was restored in just 14 to 24 seconds.

Intelligent electronic textile

Smart electronic textiles integrate electronic components such as sensors, microcontrollers, actuators, connection devices and energy sources. Traditional electronic components are mostly made of materials like metal and plastic. When they are bent, twisted or stretched, they are prone to irreversible deformation, which affects the normal function of the electronic components. However, the application of flexible materials can make up for the above problems. This type of flexible electronic component not only provides portable functions for People’s Daily lives, but also can be used to monitor human health information due to its improved interface ability with human skin. However, the traditional processing techniques for flexible electronic components have limitations when it comes to the processing of electronic components with complex functional structures. Therefore, the three-dimensional rapid prototyping processing method of 3D printing has attracted attention. At present, various 3D printing technologies have been widely applied in structural electronic devices. To enhance the adaptability to different functional requirements of products, an increasing number of flexible materials are being utilized in 3D printing technology. For instance, the polycaprolactone (PCL) synthesized by Yang Hui et al. through the chemical reaction between PCL10K and isocyanethyl methacrylate can be used as a flexible material for 3D printing. Polycaprolactone (PCL) is printed into flexible devices through commercial SLA printers and then coated with conductive materials such as silver nanoparticles or carbon nanotubes (CNTS) to form 3D printed flexible electronic devices with shape memory properties, as shown in the figure.

Among them, it consists of a 3D shape memory polymer printed object. Figure (b) shows a flexible electrical temperature sensor fabricated by adding silver nanoparticles to the surface of a 3D printed object with shape memory performance through a sintering process at room temperature. In Figure (c), when the flexible electrical temperature sensor encounters a temperature rise, its shape changes, from an open circuit to a closed circuit and the light-emitting diode lights up. Flexible sensors with shape memory behavior printed by 3D printing technology not only endow electronic devices with new functions, but also play an important role in improving product quality while changing the way people interact with electronic devices.

Conclusion

There are currently dozens of 3D printers on the market. Different types of machines can choose suitable printing materials according to requirements. However, 3D printing technology still has certain limitations in both machines and materials. 3D printed smart textiles, in addition to meeting functional requirements, should also satisfy the most fundamental fabric properties, which are all restricted by 3D printing machines and materials. Moreover, issues such as size, strength, and deformation also need to be taken into consideration. 3D printed smart textiles mainly involve the application of intelligent digital manufacturing and new materials. With the integrated development of different fields such as the textile industry, intelligent digitalization, new materials, and 3D printing technology, the production and manufacturing of smart textiles have become more flexible and are moving towards a more personalized production model.